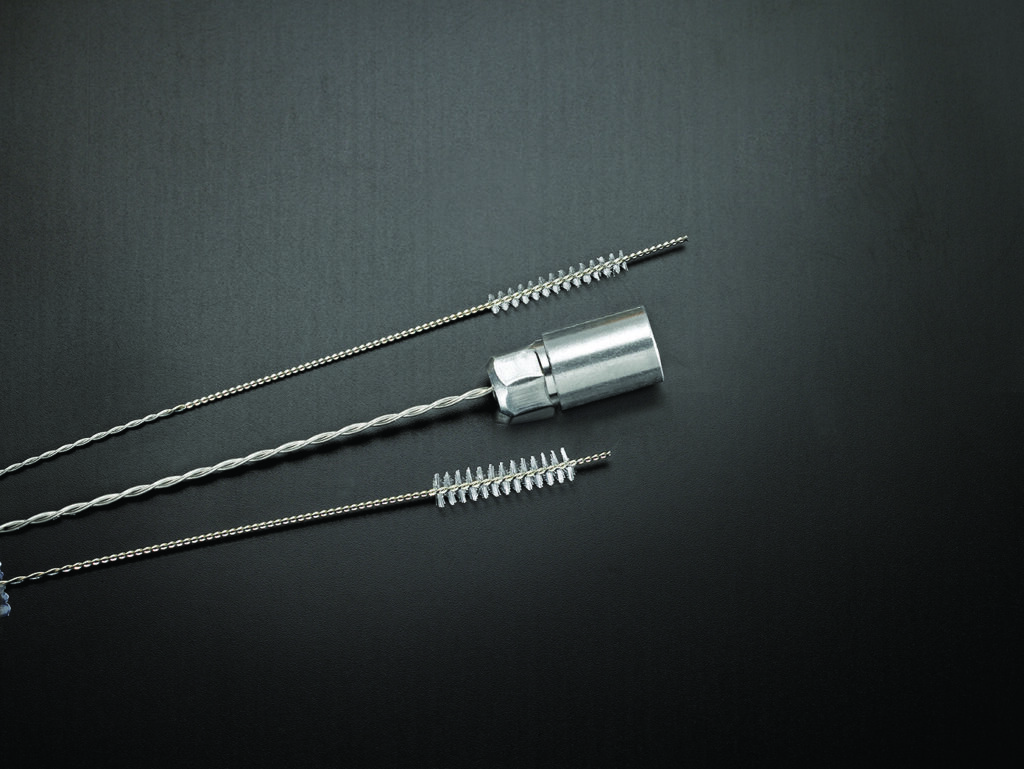

Reliable and Effective Interdental Brushes You Can Smile About

Dental Equipment Suppliers and OEMs Understand the Benefits of Quality Twisted Wire Brushes for Interdental Plaque Removal

Dental equipment suppliers have an important job—producing technology and tools that assist in effectively cleaning teeth. In the past few decades, significant research has linked the removal of dental plaque with the prevention of oral disease. It’s clear that simply brushing teeth alone does not remove plaque. Combining brushing with the practice of flossing increases the amount of plaque that is removed, but that practice is challenging if a person has difficulty using floss appropriately. Interdental brushes are easier to use than floss, and, as studies suggest, are less prone to error and more effective at removing plaque.

Sanderson MacLeod produces industry-leading, world-class twisted wire interdental brushes with distinct features not found in other brushes. As a large-quantity contract manufacturer for dental equipment suppliers and OEMs, we have worked diligently with our customers to reach beyond the demands of the marketplace. One advancement is the option of using polypropylene fibers in our endoscope cleaning, cytology, and interdental brushes.

Polypropylene fiber is a thermoplastic polymer, which is extremely durable and resistant to many chemical solvents. It is softer and gentler than traditional nylon fiber. Polypropylene fibers are available in all standard diameters and a wide variety of colors. Our polypropylene fiber brushes are available for all medical and interdental applications. All medical brush products use FDA-approved materials and are individually documented to ensure regulatory compliance. Both nylon and polypropylene brushes come standard with antimicrobial fibers.

Confidential Source Sanderson MacLeod follows a strict closed-floor production model, allowing only our own employees in the production area. This practice ensures the highest level of confidentiality when manufacturing proprietary brushes. Brushes are never outsourced to other plants, mitigating risk of intellectual property theft or misuse.

Design Breakthroughs: Sanderson MacLeod’s Efforts in Perfecting Interdental Brushes

The twisted wire brush designers and engineers at Sanderson MacLeod continuously pursue ways to perfect the interdental brush. Their efforts have resulted in countless improvements and innovations.

Through close collaboration with our customers, we leverage advanced planning, design, engineering, production, and delivery methodologies for all of our brushes. It’s through these collaborative efforts that our brush design innovation and breakthroughs happen. We work with customers to achieve desired results faster and with more accuracy, often leading to new and exciting features and products.

Domestically Produced: Twisted Wire Interdental Brushes Made in the USA

Sanderson MacLeod made the decision early on to manufacture only for OEM customers. This allows us to develop strong partnerships with customers, keep costs down, and invest in people, equipment, and technology to continually improve operations in terms of speed, quality, reliability, cost savings, and engineering design. All of our design, manufacturing, and distribution happens at our plant in Palmer, Massachusetts. The driving factor for maintaining all production and operations in the United States is that we can meet exacting standards and manufacture the highest-quality twisted wire brushes on the market.

In-House Twisted Wire Brush Scientific Research and Design Capabilities

Advances in technology, automation, and computer-aided design and manufacturing have helped propel Sanderson MacLeod’s ability to deliver world-class products to our OEM customers. But being a world leader means constantly striving to do things better. That’s why we are proud to have dedicated a part of our plant to research and science.

In our one-of-a-kind laboratory, customers can work directly with Sanderson MacLeod’s design engineers on current and future brush designs. Those designs can then be rapidly put into production to help meet customers’ needs.

Rapid Virtual Prototyping:

SanMac 3D

We turned to the software used by major motion picture animators to allow us to produce realistic renderings of design prototypes that can be easily modified. The SanMac 3D software is less expensive and faster than traditional sampling methods, letting us create virtual twisted wire brush designs that offer 360-degree visibility and industrialization feasibility testing prior to prototype build-outs. By using this method, we maximize design creativity while saving time, money, and unnecessary delays. This technology, combined with 60 years of experience and expertise, guarantees that development is quick, on budget, and ready for large-scale production.

The Sanderson MacLeod Difference

Sanderson MacLeod is the only brush manufacturer that specializes in twisted wire brushes. For more than 50 years, we have been the source of twisted wire brushes for some of the largest companies in the world. We have a demonstrated history of innovation, including the distinction of inventing the first twisted wire mascara brush.

Our company employs approximately 100 people in a state-of-the-art, 137,000-square-foot facility in Palmer, Massachusetts. We are equipped with a modern, FDA-compliant quality control laboratory to ensure that our products are of the highest quality.

A LEAN Manufacturing Company One of the most compelling aspects of Sanderson MacLeod’s business is our dedication to LEAN Manufacturing. This philosophy allows us to produce twisted wire brushes more efficiently and effectively. Enhanced inventory control systems, product use analysis, and on-floor production optimization save our customers money in innovative ways. Sanderson MacLeod has been widely recognized as a LEAN Manufacturer, leading to awards such as Business of the Year, Employer of Choice, the Super 60 Award, and the coveted ABMA William A. Cordes Innovation Excellence Award.

Our quality control department uses the latest metrology equipment, including the Nikon I NEXIV Vision system, which lets us conduct fast, accurate measurements on first-piece, in-process, and finished-good parts. Our quality control program also includes video-edge detection and automated statistical process control documentation to ensure fast, accurate, and demonstrably superior inspection capabilities.