BRUSH MARKETS

MEDICAL

BRUSH MARKETS

MEDICAL

NEXT GENERATION:

Medical

Brush

Technology

PURCHASING MEDICAL BRUSHES?

You Need A Specialist.

As a world leader in medical brush manufacturing, Sanderson MacLeod has invested heavily in making medical brushes better, safer, and more cost-competitive. From rapid prototyping in our Brush Innovation Center, exclusive material libraries, custom automation, supply stream integration (ION), to our FDA Certified manufacturing facility, Sanderson MacLeod’s team is made up of experienced brush experts who understand the complexities and demands of the medical industry.

You don’t just need a partner who makes medical brushes…You need a medical brush specialist. You need Sanderson MacLeod.

innovation and prototyping

Great Ideas Need One Thing to Become Great Products...Execution

It’s safe to say after many years and thousands of development projects under our belt, SanMac’s learned a thing or two about project execution.

And, we’ve developed the coolest tools, technology, talent and facilities around to ensure no good idea gets left behind…Ever.

Don’t Risk a Patient’s Life on the Medical Brushes You Use

When the work you do involves life or death decisions, the last thing that should be on your mind is brush-to-brush consistency and performance. Many times, brush quality and design flaws often aren’t discovered until it’s too late…and the damage is done. Good thing we’ve got you covered.

A brush is just a “brush” until it becomes a problem

Leveraging our experience and technology is a sure bet for optimum brush performance. We utilize our modern, FDA registered Quality Control test facility to effectively isolate areas for brush improvement. This helps us identify the critical tolerances needed to ensure the highest level of repeatable performance.

Sanderson MacLeod brushes take the gamble out of medical device brush sourcing.

Medical Brush Innovation

For medical brush product development and innovation clients, Sanderson’s Brush Innovation Center provides the most effective and efficient innovation process available. Services include in-house medical equipment brush testing, sample development, engineering support, and validation assistance.

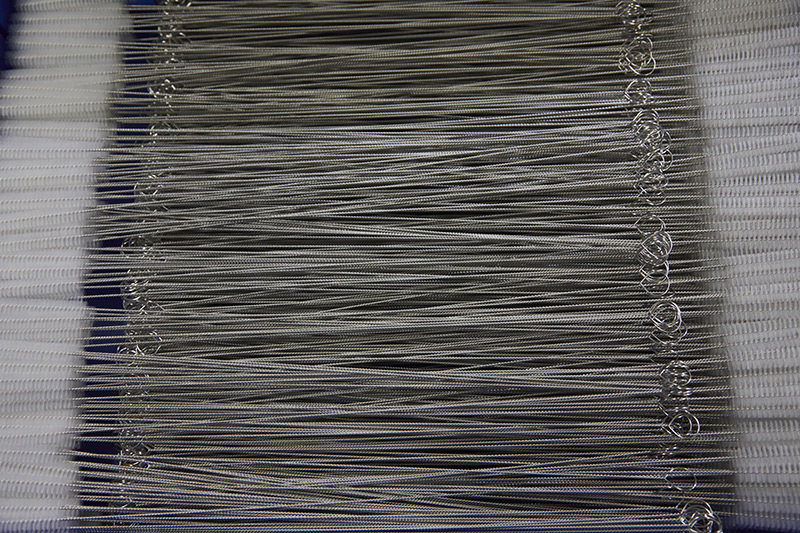

Simply seeking a trusted source for your current medical brush needs? Sanderson MacLeod specializes in contract OEM twisted wire brush manufacturing. We provide confidential sourcing, proprietary automation, flexible capacity, and cost-saving integrated supply programs.

Our tightly controlled domestic manufacturing facilities offer the latest in material technology advancements. We only use raw materials sourced from carefully selected, established, and thoroughly documented partners.

MEDICAL BRUSHES

Sanderson MacLeod makes many world-class brushes for the medical industry, including disposable and reusable medical brushes, instrument cleaning brushes, guide wires, and medical stylets.

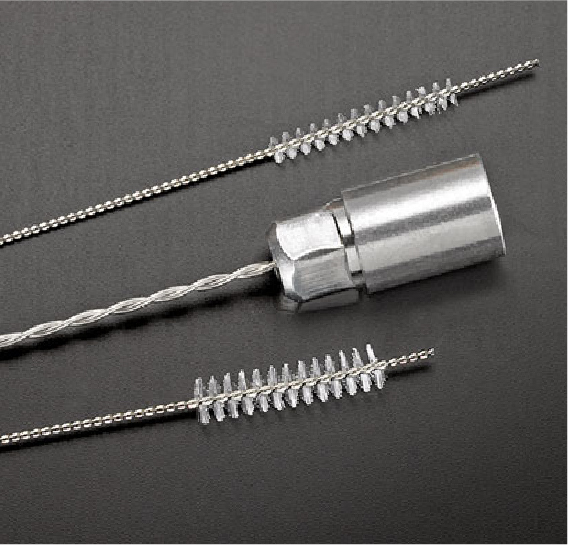

Endoscope Cleaning Brushes

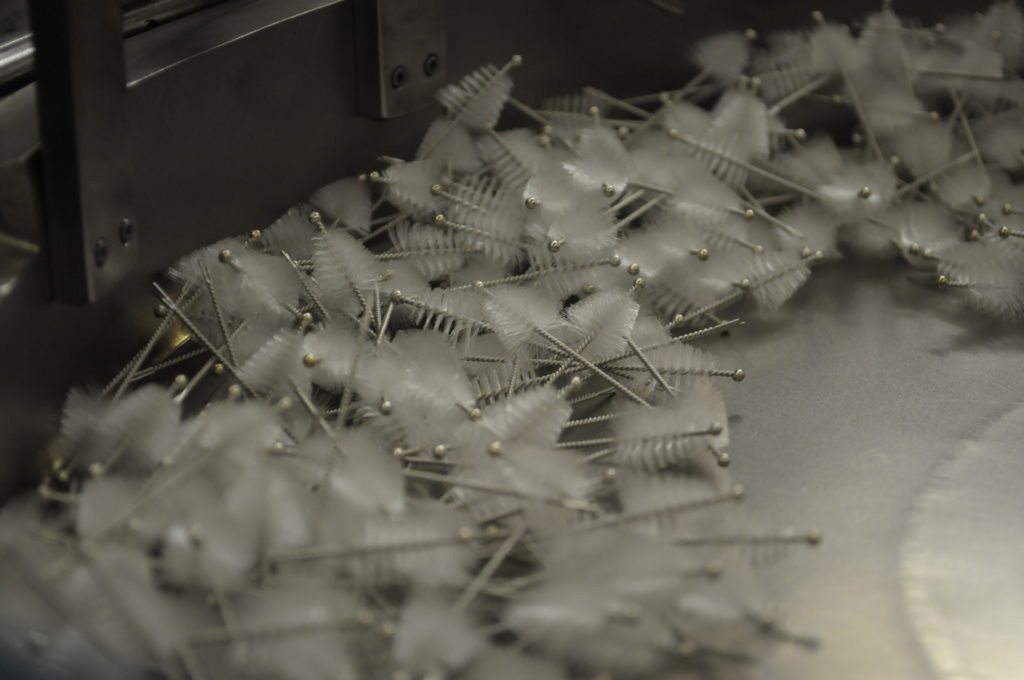

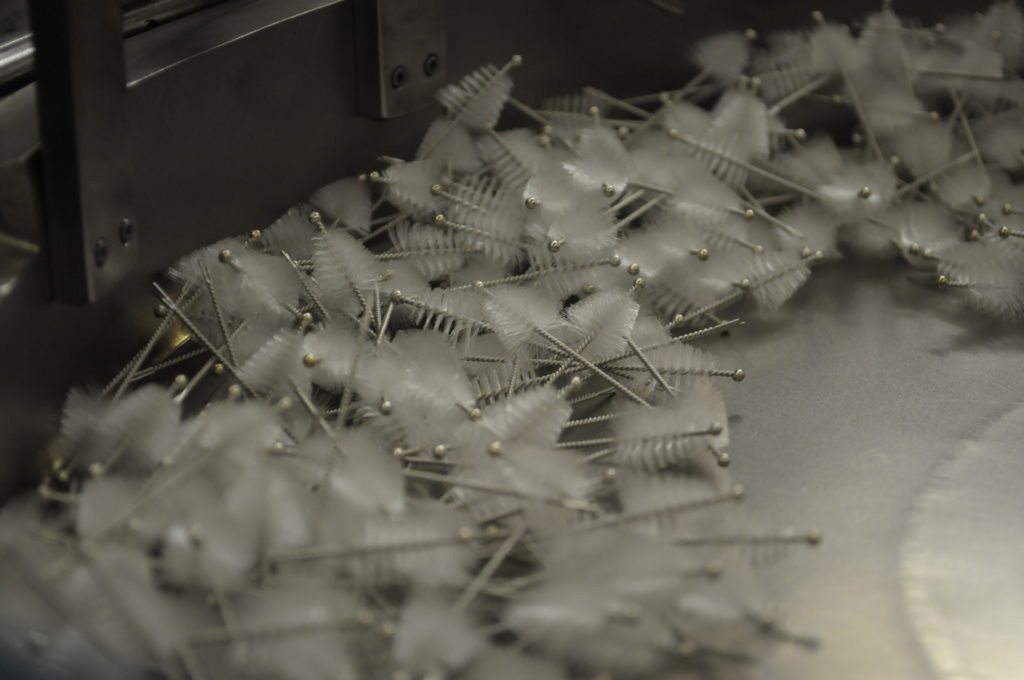

Cytology Brushes

Interdental Brushes

Design Breakthroughs: Sanderson MacLeod’s Efforts in Perfecting Medical Brushes

The twisted wire brush designers and engineers at Sanderson MacLeod pursue ways to perfect the medical brush. Their efforts have resulted in countless improvements and innovations.

By working closely with our customers, we leverage advanced planning, design, engineering, production, and delivery processes for all of our brushes. It’s through these group efforts that our brush design innovation and breakthroughs happen. We are proud to employ the most skilled brushmakers in the industry. We work with customers to achieve desired results faster and with more accuracy. Our process often leads to new and exciting features and products.

The ZTip™ Surgical Instrument Cleaning Brushes Prevent Equipment Damage

Sanderson MacLeod has been an innovator in the twisted wire brush industry by constantly researching better ways to solve customer problems. When the company set out to fix flaws in medical brush tips, we completely changed the brush industry.

The largest risk for medical equipment damage can occur during cleaning with a brush that is inserted into the equipment. Traditional brush tips can fall off, sharp core wires can protrude from the tip, and the tips can bend and break.

We solved these problems by looking outside of the brush industry. We worked with experts in materials joining engineering. We conducted hundreds of hours of research, trials, and testing. Through the research, we were able to create a new manufacturing process that uses high-energy, fusion-welding technologies.

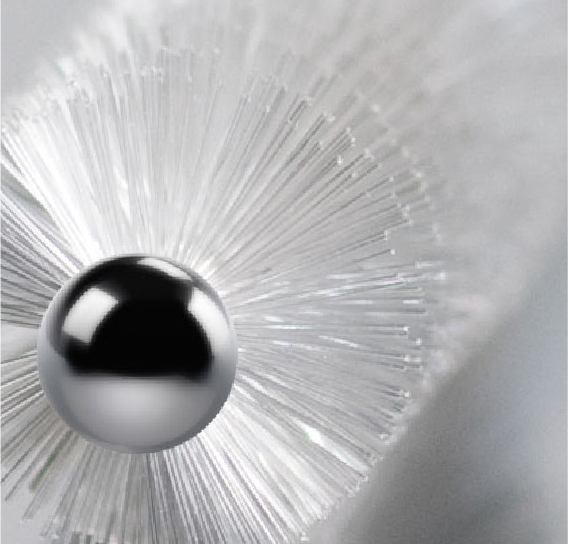

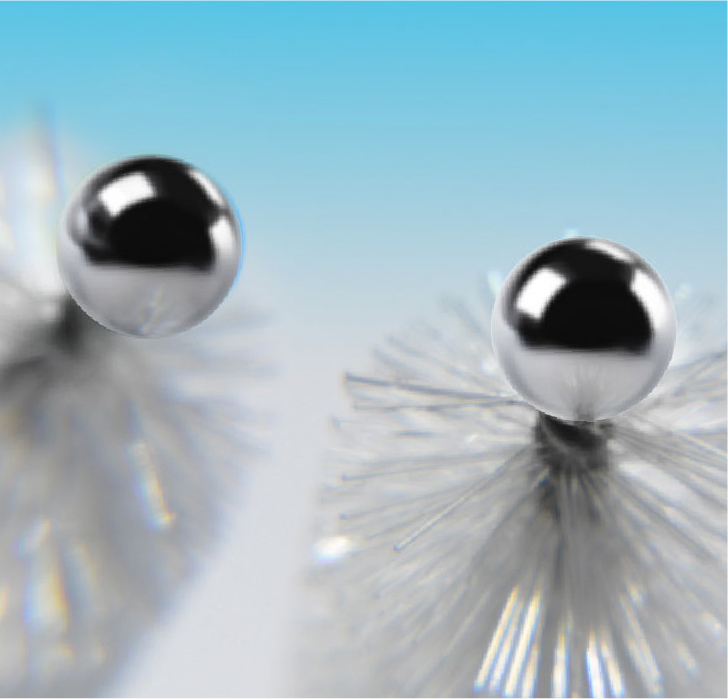

The result is an entirely new protective brush tip. The process melts the brush’s preconstructed core wire into a consistent, smooth stainless steel protective tip that cannot be separated. It is known as the ZTip.

In addition to this innovative design, we produce a brush tip with a mirror-like smooth surface. This brush tip can’t fall off. The brush’s core wire won’t protrude through the tip, and the dimensions and position are always consistent.

The ZTip twisted wire medical brush is created in one in-line, fully automated process. The biggest benefit of this process is the reduction of internal inspection time and costs.

The most important aspect of the ZTip is that it will not create microscopic scars while cleaning medical equipment. By not creating scars that trap contaminants, the ZTip promotes medical equipment sterility. The ZTip is available for all commonly used twisted wire medical brush applications.

Large-Volume, Manufacturer-Direct Medical Brushes for Every Purpose

Product Assurance

Sanderson MacLeod employs first-piece, in-process, and final-piece inspection for all products. We staff highly trained quality inspectors 24 hours a day.

As a contract manufacturer for medical equipment cleaning suppliers and OEMs, we have worked diligently with our customers to reach beyond the demands of the marketplace. One advancement is the option of using polypropylene fibers in our endoscope cleaning, cytology, and interdental brushes.

Polypropylene fiber is a thermoplastic polymer, which is extremely durable and resistant to many chemical solvents. It is softer and gentler than traditional nylon fiber.

Polypropylene fibers are available in all standard diameters and a wide variety of colors. Our polypropylene fiber medical brushes are available for all medical applications. All medical brush products use FDA-approved materials and are documented to ensure regulatory compliance. Both nylon and polypropylene brushes come standard with antimicrobial fibers.

Confidential Source

Sanderson MacLeod follows a strict closed-floor production model, allowing only our own employees in the production area. This practice ensures the highest level of confidentiality when manufacturing proprietary brushes. Brushes are never outsourced to other plants, mitigating the risk of intellectual property theft or misuse.

Looking for a brush quote?

Whether you have a current brush and want to take advantage of Sanderson MacLeod’s large volume direct manufacturing pricing or want to work with our team of engineers on a new design, we have you covered.